Need to make sure your foundation is solid? A heavy duty plate compactor is the machinery for the job. Renting one from a nearby rental store gives you the capability to compress soil efficiently and thoroughly.

Whether you're putting down pavers, gravel or asphalt, a heavy duty plate compactor will help you achieve a level outcome. We offer a range of compacting Compactor plates in different weights to match your specific project needs.

Call our friendly team today to explore your heavy duty plate compactor rental options.

Soil Compaction: The Power of a Vibratory Plate

A vibratory plate acts as a powerful tool for soil compaction tightening in construction and landscaping projects. By applying kinetic force to the ground, this machine effectively reduces voids within the soil, resulting in a more stable and compact foundation for structures or paved surfaces.

The process of compaction is crucial because it strengthens the soil, preventing settlement and providing a uniform surface for construction. Vibratory plates are particularly effective in firming granular soils like sand and gravel, as well as clay-based soils.

They can be used to prepare areas for foundations, create level ground for patios, or stabilize slopes to prevent erosion.

The vibratory plate is a versatile and essential tool for any project that requires soil compaction, ensuring the long-term stability and durability of your construction or landscaping endeavors.

Optimal Site Preparation with Compactors

When starting a construction project, proper site preparation is paramount. This encompasses removing debris, leveling the ground, and compacting the soil to create a stable foundation. Compactors play a crucial role in this process, ensuring that the subgrade is firm and level, thus minimizing future settling and potential issues.

- Opting for the right compactor depends on the nature of the site.

- Work well in smaller areas, while sheepsfoot rollers are better suited for larger projects.

- Routine care of compactors is crucial to ensure optimal performance and longevity.

Choosing the Perfect Compactor Machine to suit your requirements

Navigating the world of compactor machines can feel overwhelming. With a multitude of options available, each boasting different capabilities, pinpointing the ideal fit for your particular applications requires careful consideration. This detailed overview aims to demystify the process, providing you with the knowledge required to confidently select a compactor machine that perfectly complements your operational needs.

- To begin with clarifying your precise criteria. What type of materials will you be compacting? What volume ? Think about your budget, available space, and the frequency of use.

- Subsequently, delve into the multiple models of compactors available. Explore options like plate compactors, roller compactors, rammer compactors, and pneumatic compactors. Each type possesses distinct advantages for diverse situations.

- Lastly, contrast the specifications of shortlisted machines. Consider carefully engine power, compaction force, weight, fuel efficiency, and ease of maintenance. Reading testimonials from other users can also provide valuable insights.

Comprehending Soil Compaction for Construction Projects

Soil compaction is a vital consideration in construction projects, influencing the stability and durability of structures. Compacted soil provides a stable foundation, reducing the risk of subsidence. During construction, heavy machinery and equipment can compress the soil, resulting in changes in its density and strength.

It's necessary for contractors to comprehend the process of soil compaction and implement proper measures to maintain a suitable foundation. Various factors, like soil type, moisture content, and compaction equipment, can affect the effectiveness of compaction efforts.

Properly compacted soil decreases the risk of foundation failures and other construction problems.

Conversely, poorly compacted soil can lead to sinking, weakness, and increased maintenance costs.

To achieve optimal compaction, contractors employ specialized equipment, such as vibratory rollers or plate compactors, which energetically densify the soil layers. Precise monitoring of moisture levels and compaction density is important to guarantee a stable and durable foundation for construction projects.

Industrial Grade Soil Compactors: Built to Last

When you demand a soil compactor that can handle the toughest jobs, look no further than an industrial grade model. Built with sturdy components and precision engineering, these machines are designed to withstand years of continuous use. From compacting gravel and dirt to preparing foundations for construction, an industrial grade soil compactor will guarantee exceptional performance and reliability in any setting.

- Specifications of industrial grade soil compactors often include powerful engines, durable tires, and adjustable compaction forces to ensure optimal results for a spectrum of applications.

- These machines are also equipped with safety mechanisms such as operator shields and emergency halt buttons to minimize the risk of accidents.

Investing in an industrial grade soil compactor is a smart decision for any construction or outdoor improvement professional who emphasizes durability, performance, and safety.

Ross Bagley Then & Now!

Ross Bagley Then & Now! Danica McKellar Then & Now!

Danica McKellar Then & Now! Sam Woods Then & Now!

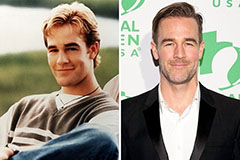

Sam Woods Then & Now! James Van Der Beek Then & Now!

James Van Der Beek Then & Now! Robin McGraw Then & Now!

Robin McGraw Then & Now!